QuantumCOLOUR™

REVOLUTIONIZING THE TEXTILE INDUSTRY’S APPROACH TO DYEING AND FINISHING.

QuantumCOLOUR™ for Yarn

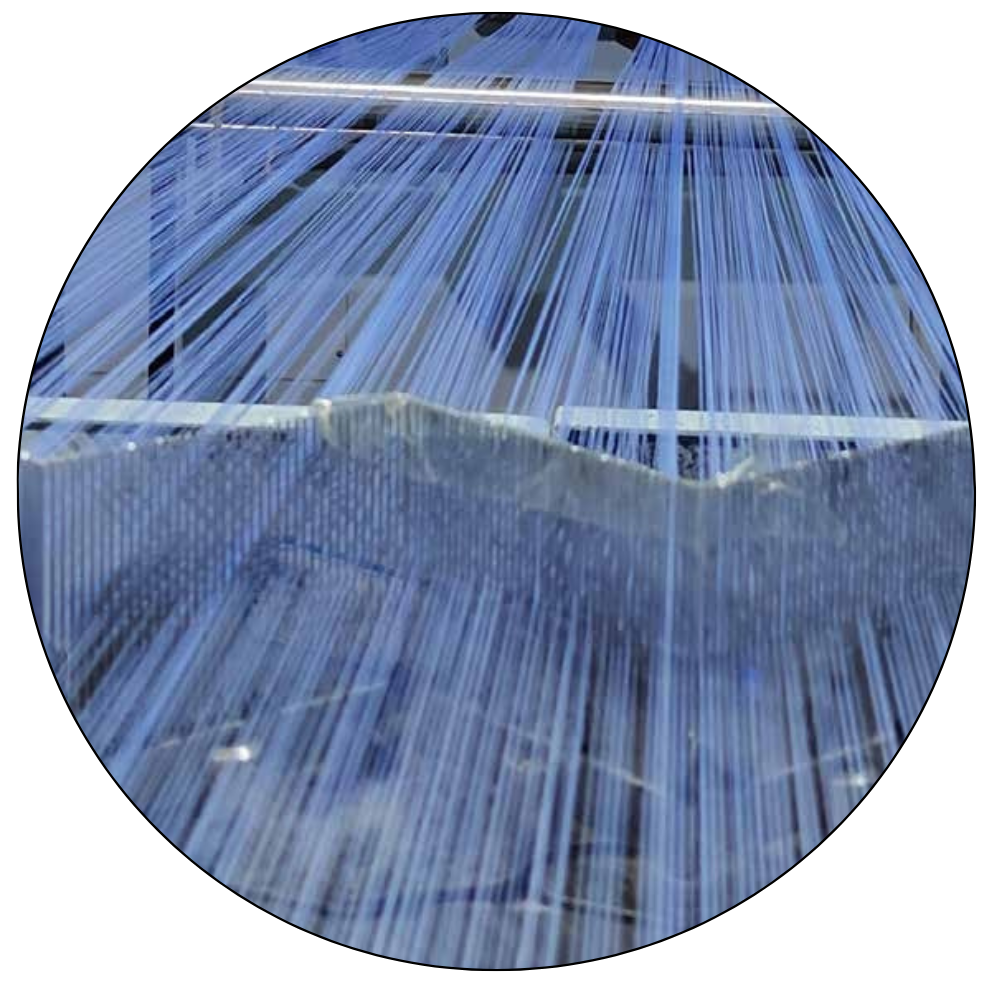

Sustainable Yarn Coloration

An innovative, radically sustainable commercial technology for coloring cellulosic and synthetic yarns

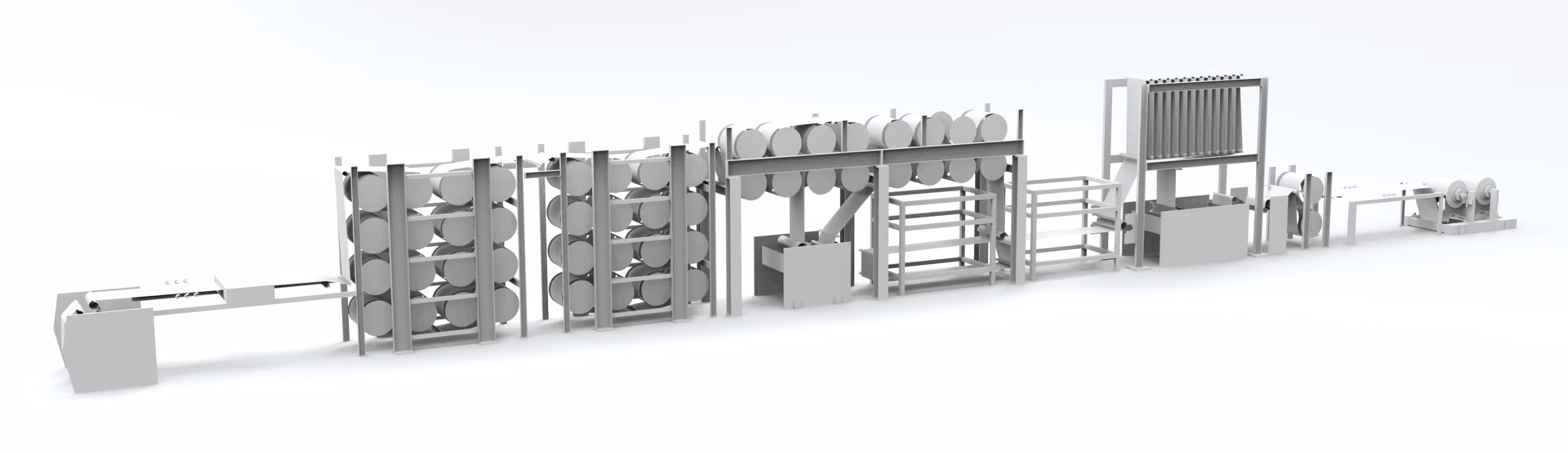

Production-Proven

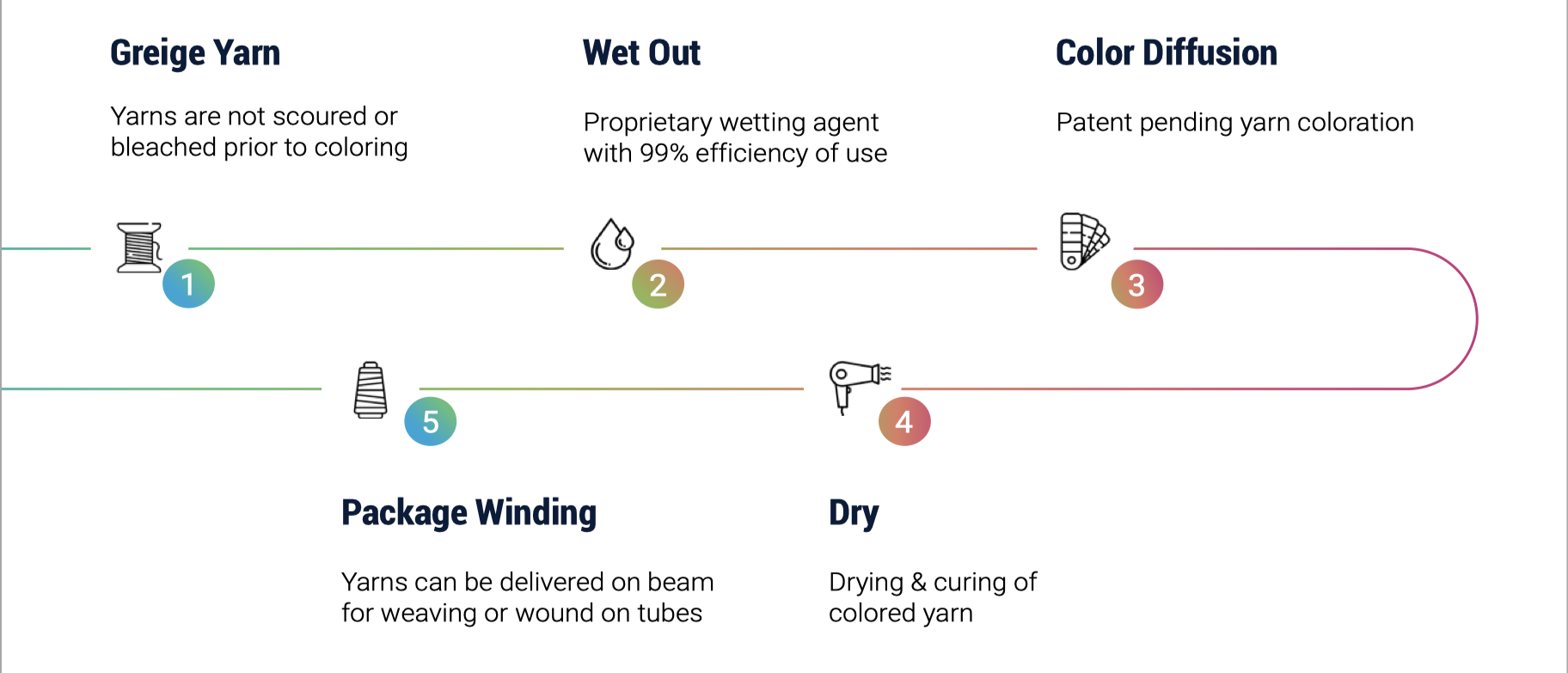

The culmination of over 10 years of research and investment, QuantumCOLOUR™ for yarn meets the rigorous standards of industrial manufacturing with its game-changing 5-step process, simplifying and streamlining the 30+ steps of conventional dyeing.

QuantumCOLOUR™ systems for yarn are currently running in high volume production, with capacities of 26,000Kgs to 96,000Kgs of yarn per month per machine.

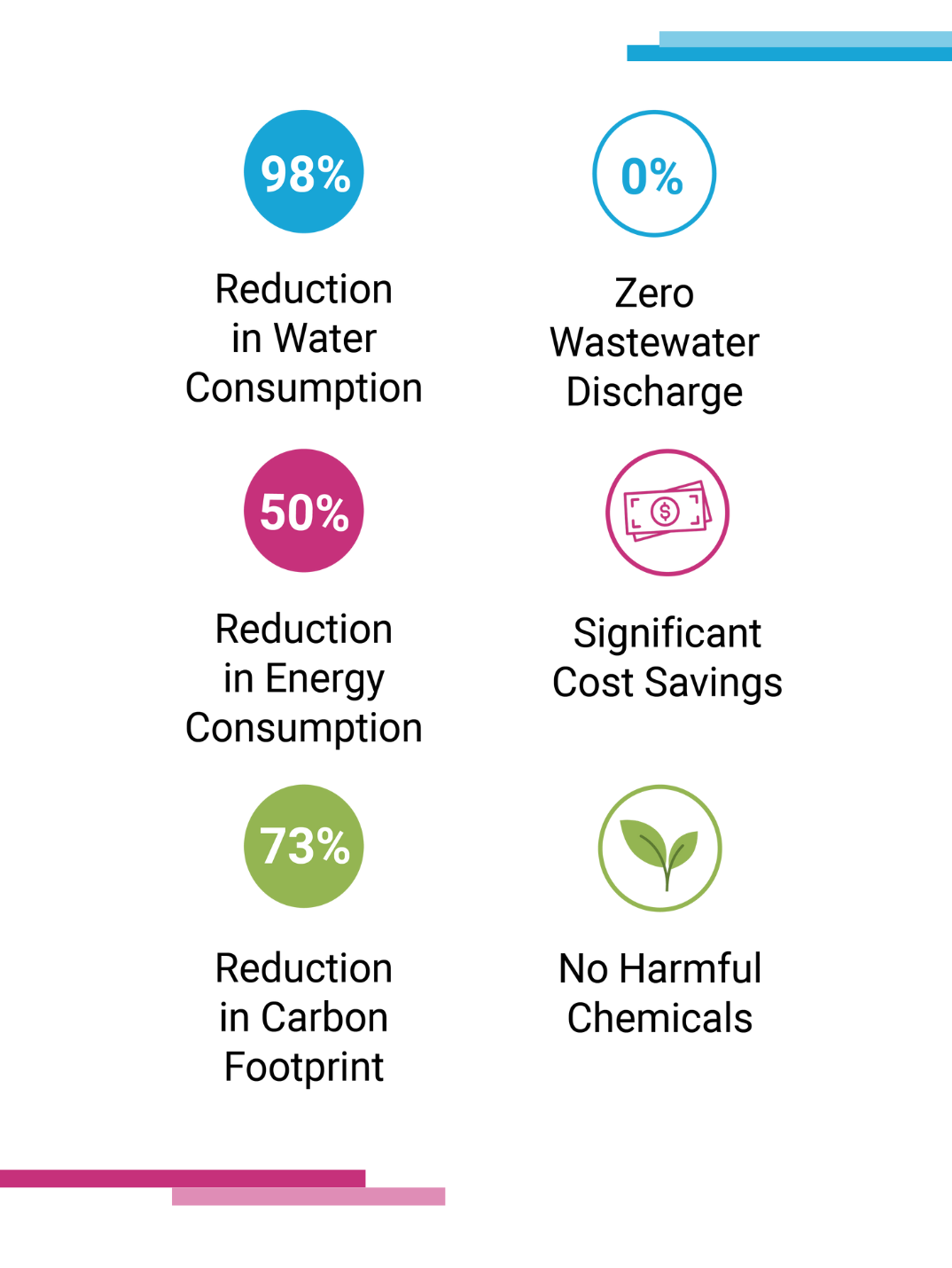

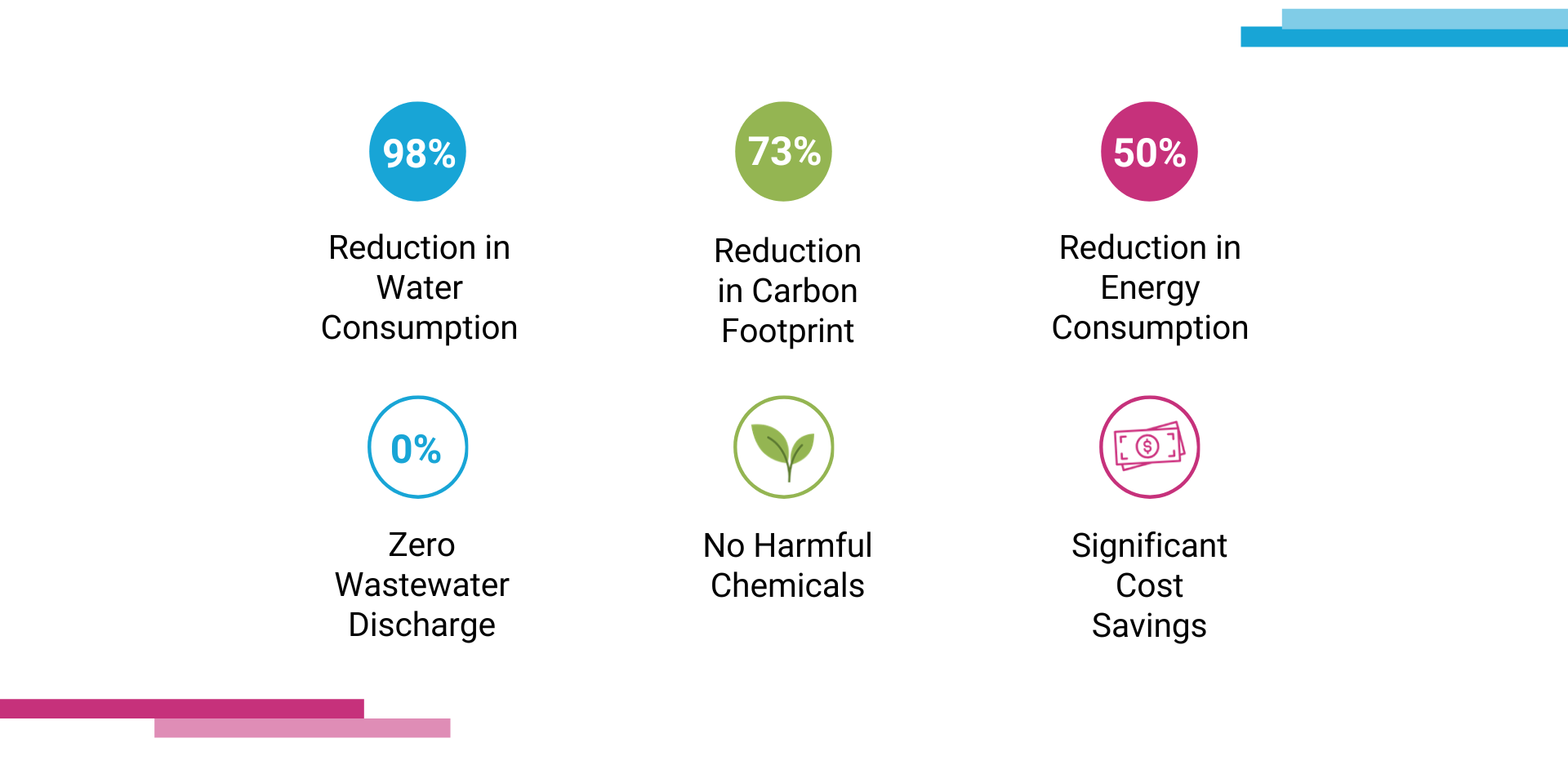

SUSTAINABILITY CONFIRMED

Water Savings

COLOURizd™ has approached the textile coloration process from a new and disruptive perspective, one that challenges existing paradigms, enables a dry and non-polluting factory environment, and eliminates costly and time-consuming finishing steps.

Lower Carbon Footprint

Our customers (and brands) are urgently seeking ways to manufacture apparel and home products while reducing their environmental impact. Using QuantumCOLOUR™ equipment can help to embed sustainability into products, improving competitive differentiation and enhancing public image.

Reduction in Energy Use

The cozy, informal and comfortable prewashed look is a desirable appearance that is targeted by many brands and represents the bulk of fabric created for the casual market in both home and apparel. Before QuantumCOLOUR™ , it also represented a wasteful and polluting manufacturing process — but no longer!

PRODUCT INFORMATION